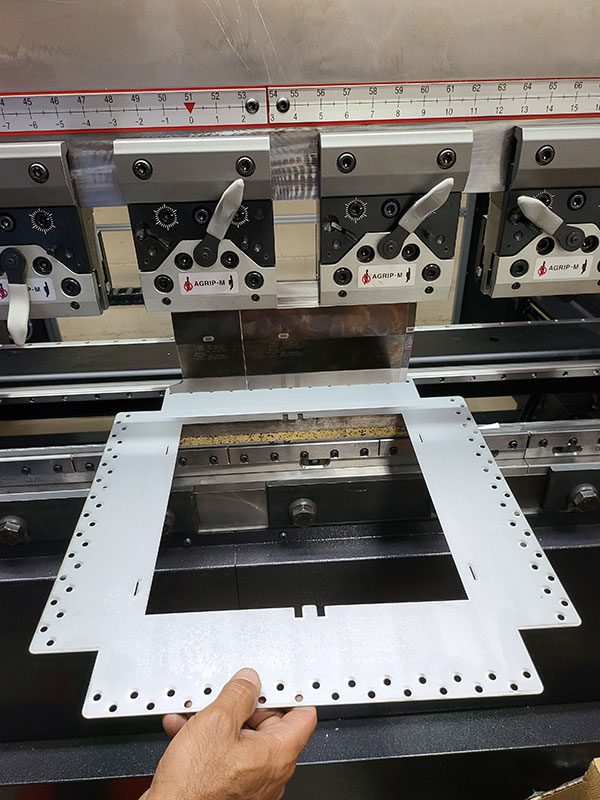

Weldflow has different tonnage and sizes All Steel, Ermak and Wysung make press brakes. There are 6 different press brakes with variety of configuration. This enables Weldflow production team to allocate jobs with least amount of time in change overs and set-ups. All our press brakes have numerically controlled back gauges. With some press brakes, we have capability of 5 axis movement and fully computerized with off line programming capabilities.

Weldflow has different tonnage and sizes All Steel, Ermak and Wysung make press brakes. There are 6 different press brakes with variety of configuration. This enables Weldflow production team to allocate jobs with least amount of time in change overs and set-ups. All our press brakes have numerically controlled back gauges. With some press brakes, we have capability of 5 axis movement and fully computerized with off line programming capabilities.

Weldflow Metal continually strives for improvement in our services, and we’re thrilled to announce our latest step forward: the addition of the Press Brake HG8025 M15 to our production line. This powerful machine will significantly enhance our sheet metal service offerings.

Unleashing Accuracy through the Press Brake HG8025 M15

The HG8025 M15 is not merely a piece of machinery. It embodies AMADA’s unwavering dedication to precision and high performance. This machine stands out with its environmentally friendly electric/hydraulic down-acting system, well-known for delivering unmatched accuracy. It features a hybrid drive system that significantly reduces energy consumption and hydraulic fluid usage, embodying the spirit of sustainability. Additionally, its sophisticated ram precision ensures extraordinary consistency.

But what does this cutting-edge machine mean for our services, and why is it important to you?

The HG8025 M15 Impact: Delivering Services that Surpass Expectations

- Increased Accuracy: The HG8025 M15 allows us to provide a higher level of precision in our customized sheet metal laser cutting services, guaranteeing that your project aligns with the exact specifications needed.

- Eco-friendly Manufacturing: This machine is environmentally friendly, consuming less energy and hydraulic fluid than traditional systems. When you opt for Weldflow Metal, you are investing in not just precision, but sustainable manufacturing processes as well.

- Boosted Efficiency: The HG8025 M15 enables us to optimize our operations, reducing time wasted on setups and changeovers. For you, this means quicker service, punctual project completion, and an overall efficient experience.

Why Weldflow Metal Should Be Your Go-To For Product Services?

We provide more than just sheet metal services; we deliver solutions specifically designed to meet your unique needs. Our diverse lineup of press brakes, featuring brands like All Steel, Ermak, and Wysung, allows us to tackle projects of any scale and complexity.

Our numerically controlled back gauges, in combination with the 5-axis movement capability of some of our press brakes, enable us to accomplish tasks with the highest level of precision and efficiency. These technological benefits translate into top-quality, timely services for you.

Discover the Weldflow Metal Difference in Sheet Metal Services

The Press Brake HG8025 M15 is not just a new piece of equipment—it’s a game-changer. With this state-of-the-art machine incorporated into our production line, we are ready to offer unrivaled custom sheet metal laser cutting services. We invite you to discover the superior service that is Weldflow Metal. Contact us today to start your project, and let’s collaboratively build a successful future.