If you have a business in New York, and you’re interested in implementing laser parts and components as part of your internal operations or for the manufacturing of consumer goods, there are ways to ensure success. Taking the right steps will not only help you succeed but also save you valuable time and money. To implement laser cutting in your NYC business, you need both knowledge and sound strategies.

There are several factors to consider when using custom laser cutting services.

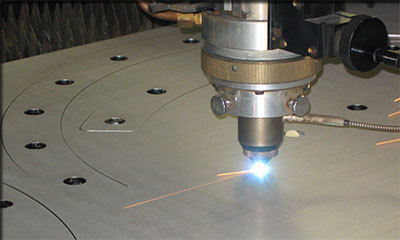

1. Fabrication Company – The quality of the finished product depends heavily on the experience and expertise of the laser cutting company that you select. For that reason, you’ll need to choose a reputable company that has a long history of achieving customer satisfaction. The right company uses state-of-the-art equipment and superior-quality raw materials and has a full team of experts in-house to help with various projects.

2. Planning – Even if you have an innovative idea, you must put a plan in place to bring it to fruition. For instance, a lot of customers have great designs in mind, but they don’t know how to organize and plan them. This is where a top-rated laser cutting company can help. By choosing one with an engineering design team, you’ll have an abundance of help, so you can move forward with having products fabricated.

3. Tracking – You’ll need a reliable tracking system to implement laser cutting solutions in your NYC business. The goal is to keep track of concepts, designs, prototypes, finished products, delivery dates, cost, and so on. You also want to track the budget, potential risks, actions, and decisions. That way, you accomplish three things. First, you have a running history of the different fabricated products you’ve implemented. Second, you keep every project 100 percent transparent. Third, this will make your internal team accountable for their respective responsibilities.

4. Teamwork and Organization – When it comes to using custom laser cutting services to help your business succeed, you need a lot of teamwork and organization. Especially if this is a new facet of your organization, everyone needs to have a clear understanding of their role. That includes employees who work on designs, those that save the designs in CAD or another type of computer program, and one or more designated points of contact who work directly with the laser cutting company.

5. Prototypes – It’s to your advantage to have prototypes of your design made before going into full product production. The top companies that offer laser cutting in NYC provide this service. Using the mock model, you can identify any design flaws that would compromise the finished part or component. That gives the fabricators the chance to make the appropriate changes, saving you a lot of time and money.

Turn to the Best

When you need custom laser cutting services, turn to the best – Weldflow Metal Products. Call us today to discuss your needs.