If you are interested in laser cutting metal fabrication services, conduct research to better understand the pros and cons. With the information gathered, you will be able to determine if this is the right service for your specific job.

Pros

* Custom Fabrication – Custom fabrication is easier to achieve using laser cutting technology compared to other methods. If you need a unique part or component fabricated, this is an excellent choice.

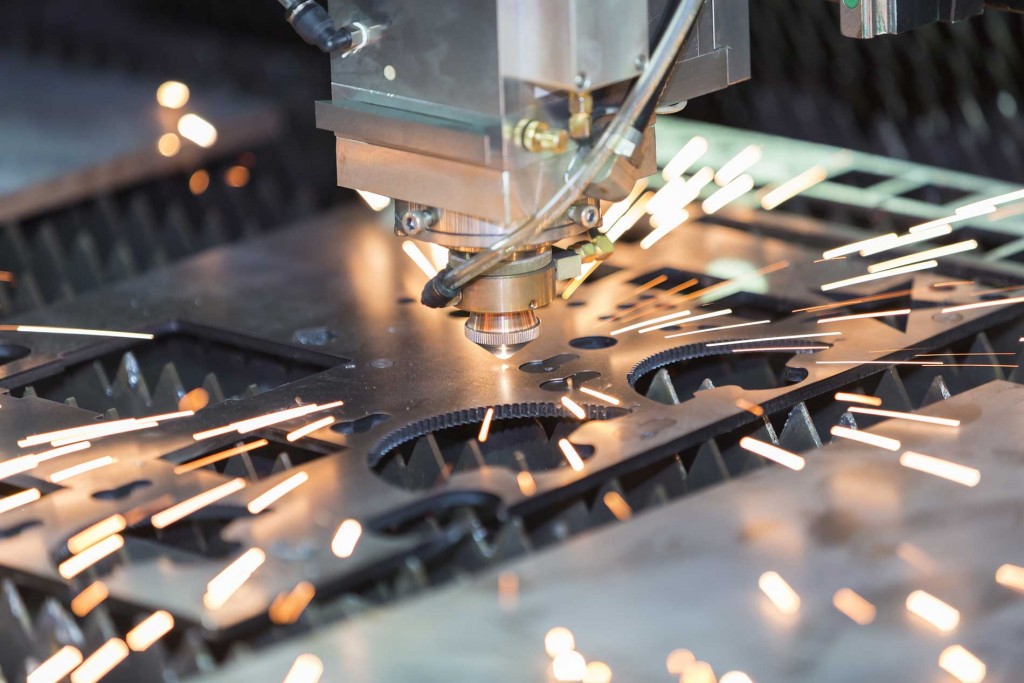

* Faster Production – With laser cutting, the generated laser beam cuts through material in less time compared to water-jet, plasma, and mechanical cutting. With the beam of light being so focused and intense, it burns the workpiece more precisely, which dramatically reduces the amount of labor time required. In addition, there is no cleanup, again speeding up the production process.

* Zero Mechanical Breakdowns – With water-jet or mechanical cutting, mechanical breakdowns are common. Because the only type of fabrication equipment required with laser cutting is the laser itself, there are no mechanical components to break down.

* Greater Precision – There is little risk to laser cutting causing damage or deformity to the workpiece, especially when working with metal. As a result, the level of precision for the finished product excels above what other techniques produce.

Cons

* More Expensive – Compared to other cutting techniques, laser cutting is the more expensive option. However, considering all of the advantages, most people agree it is a worthwhile investment.

* Limitations – For certain materials, including brass and copper, this type of cutting with CO2 is not recommended. However, this limitation can be overcome with Fiber Laser.

What is Fabrication in Manufacturing?

If you are confused as to what fabrication is in relation to manufacturing, there is a simple explanation. Fabrication is a term used in the industrial world that describes the manipulation of steel and other raw materials used for making parts, components, structures, machines, and so on. During the fabrication process, the workpiece, which is the material, is cut and shaped according to the required specifications. In other words, fabrication is the hands-on portion of the manufacturing process.

Finding Metal Fabrication Shops Near Me

If you are searching for a top-quality metal fabrication shop, look no further than Weldflow Metal Products. With many years of experience and unrivaled expertise, you can expect a superior finished product. You can visit our website to learn more about our company or to view all of the services that we provide. If preferred, you can contact us by phone and speak with a team expert.