Today, stainless steel fabrication stands as a testament to human innovation and creativity. This versatile material has redefined what’s possible in construction, enabling the creation of awe-inspiring structures that push the boundaries of imagination.

In this article, we’ll delve into the intricate process of the same and shed light on the pivotal role played by reputable companies in bringing visionary concepts to life.

What Is The Process of Steel Fabrication?

Stainless steel fabrication is not just about welding and bending sheets of metal; it’s a precise and complex process that demands craftsmanship and expertise. The process involves several stages, each contributing to the transformation of raw stainless steel into functional and aesthetic wonders.

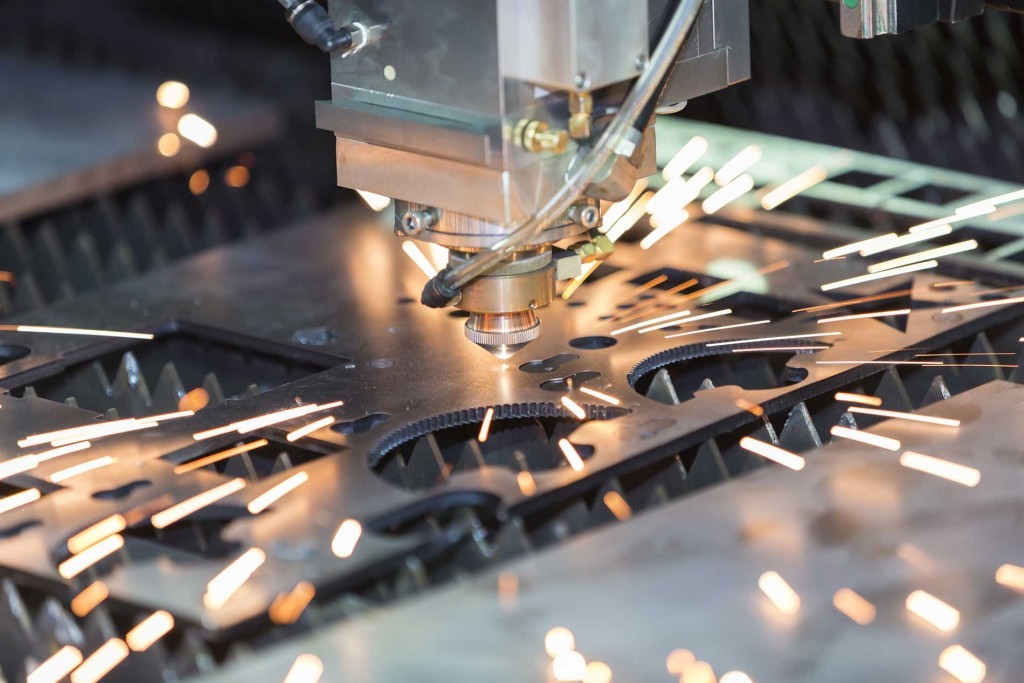

- Cutting and Shaping: The journey begins with cutting and shaping the stainless steel sheets according to precise measurements. Computer-controlled machinery ensures accuracy down to the millimeter, setting the stage for the subsequent phases.

- Forming and Bending: This is where the magic happens. Skilled technicians use various techniques, such as rolling and press braking, to bend and shape the stainless steel into intricate forms. This stage requires a deep understanding of the material’s properties and behavior under pressure.

- Welding and Joining: Seamless joining is crucial in this steel’s fabrication. Advanced welding methods, including TIG and MIG welding, are employed to fuse different pieces together. This results in strong and durable connections that maintain the structural integrity of the final product.

- Finishing Touches: Once the structure is assembled, it undergoes meticulous finishing. This includes polishing to achieve the signature stainless steel luster and applying protective coatings to enhance durability and resistance to corrosion.

The Role of a Reputable Stainless Steel Fabrication Company

Behind every iconic architectural marvel, there’s a reputable stainless steel fabrication company that has contributed its expertise. These companies are not merely manufacturers; they are partners in turning visionary concepts into tangible reality.

- Precision Engineering: A dedicated company like Weldflow Metal Products will combine engineering prowess with artistic sensibility. Their teams of engineers, designers, and craftsmen work collaboratively to ensure that every curve, angle, and joint aligns flawlessly with the original design.

- Customized Solutions: No two design projects are alike. This is where customized sheet metal fabrication comes into play. These companies excel at tailoring their processes to suit the unique requirements of each project, whether it’s a futuristic skyscraper or an avant-garde sculpture.

- Innovation and Prototyping: Innovation drives the steel fabrication industry. These companies invest in research and development to explore new techniques and materials that can elevate the quality and aesthetics of their creations. Prototyping allows them to test and refine ideas before full-scale production.

- Sustainability and Future-Proofing: As the world becomes increasingly conscious of sustainability, companies like Weldflow Metal Products are leading the charge. They incorporate eco-friendly practices into their processes and ensure that their creations stand the test of time, both in terms of design and durability.

Conclusion

Stainless steel fabrication is a symphony of artistry, engineering, and innovation. It’s a journey that starts with raw materials and culminates in architectural and design marvels that defy expectations. Companies like Weldflow Metal Products are the orchestrators of this journey, bringing dreams to life with precision, expertise, and a commitment to pushing the limits of what’s possible. So, the next time you marvel at a gleaming skyscraper or an intricately designed structure, remember that behind its creation is the intricate world of stainless steel fabrication.