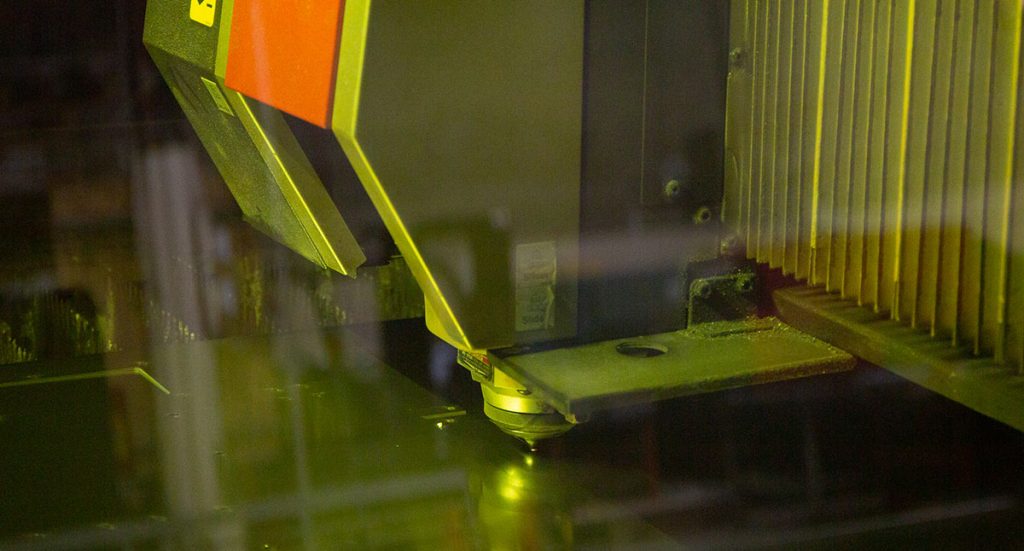

Do you know how the choice of metal affects the outcome of your laser cutting projects? Selecting the right material is crucial for precision, efficiency, and achieving the desired finish. Advances in sheet metal laser cutting technology mean your material choice greatly influences the project’s quality and cost-effectiveness. Whether you’re working on intricate designs or durable components, understanding the unique properties of each metal can elevate your results. Let’s explore the six ideal metals that promise superior outcomes in the sheet metal laser cutting service, ensuring your projects meet and exceed expectations.

-

Aluminum: Combining Lightness with Strength for Precision Cutting

Aluminum truly shines in laser cutting applications, blending its lightweight nature with remarkable strength. This metal is a top pick for sectors like medical and consumer electronics, where precision and efficiency are non-negotiable. Its superior thermal and electrical conductivity, coupled with an inherent resistance to corrosion, positions aluminum as the go-to material for your intricate laser cutting needs. Whether you’re crafting delicate components or robust machinery parts, aluminum ensures your projects benefit from top-tier performance without the extra weight. Embrace aluminum’s versatility to elevate your laser cutting projects to new heights.

-

Stainless Steel: Ensuring Durability and Precision in Every Cut

When you choose stainless steel for your laser cutting projects, you’re selecting a material celebrated for its exceptional strength and steadfast resistance to oxidation and corrosion. This metal’s remarkable durability makes it an ideal choice for critical applications in industries like medical and food processing, where hygiene and longevity are paramount. Its adaptability across various sectors underscores stainless steel’s reliability in delivering precise cuts every time. Opt for stainless steel in your next project to guarantee accuracy and a lasting resilience that stands the test of time.

-

Copper: Mastering Precision in Conductive Applications

Copper’s unparalleled electrical conductivity positions it as a cornerstone in manufacturing electrical components and heat exchangers. Historically, its reflective nature posed challenges for laser cutting, but advancements in sheet metal laser cutting technology have revolutionized this process. Now, achieving precise, clean cuts in copper is not just possible; it’s a reality. If you’re looking to elevate the quality of your conductive applications, embracing modern laser cutting services can transform how you work with copper, ensuring your projects benefit from its exceptional properties without compromise.

-

Brass: Blending Aesthetics with Functionality in Laser Cutting

Brass, with its striking gold-like appearance and superior machinability, stands as the premier choice for both decorative and functional components. Its remarkable low friction coefficient and resistance to tarnishing enhance its suitability for elaborate designs that demand a sophisticated touch. When you opt for brass in your laser cutting projects, you’re choosing a material that effortlessly marries aesthetics with functionality. Ideal for creating pieces that require precision along with an elegant finish, brass ensures your projects stand out with unparalleled beauty and performance.

-

Satin Coat: Innovating with Corrosion Resistance for Detailed Cuts

If you’re tackling projects that demand both durability and precision, consider satin coat steel. This innovative material, coated with a thin zinc layer, significantly boosts corrosion resistance without compromising the steel’s inherent strength. It’s an exceptional choice for outdoor applications or any environment where moisture is a concern. The zinc coating ensures your projects withstand the elements, making satin coat steel ideal for detailed laser cutting services where longevity and precision are key. You can choose a satin coat for your next project and experience the perfect blend of resilience and accuracy.

-

Galvanized Steel: Combining Protection with Precision in Laser Cutting

Galvanized steel, with its robust zinc coating, stands as your shield against rust and corrosion, making it the material of choice for various components. Its durability and precision in laser cutting ensure that your projects not only withstand the test of time but also meet the highest standards of accuracy. Ideal for environments where strength and longevity are critical, galvanized steel offers you a reliable solution for your most demanding projects. Choose the unmatched protection and precision of galvanized steel with Weldflow Metal Products’ steel plate cutting services in your next laser cutting endeavor.