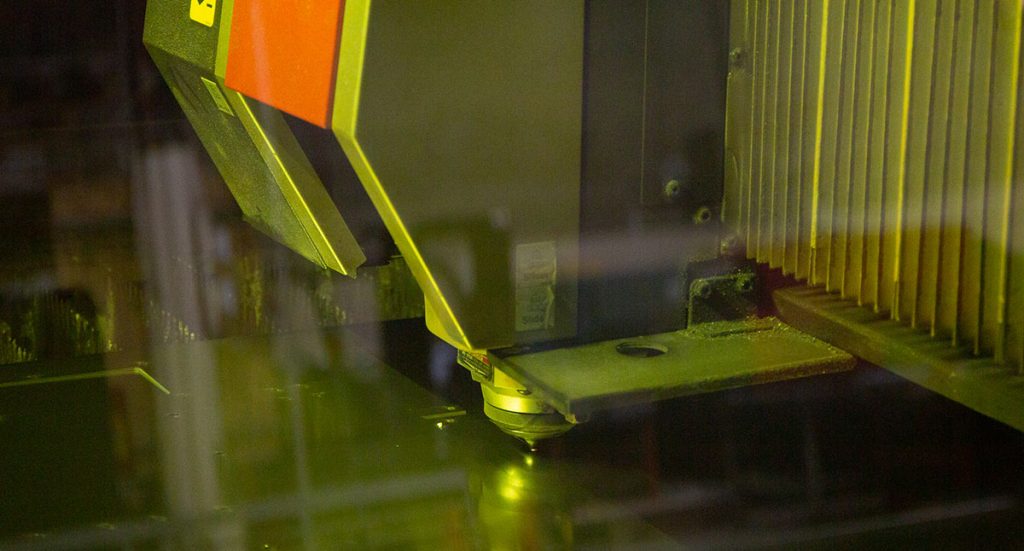

If you use laser cutting for your company, then you most likely know that the different surfaces of metal can have different properties when it comes to cutting with a laser. The better the material you have, the better the cutting will be. But when it comes to laser cutting, the surface of the material is not the only factor affecting the outcome. Many other factors can play critical roles in cutting the surface of a sheet. From the temperature of the sheet to the operator, every aspect can affect the final product in metal laser cutting services.

The Thickness of the Surface

The speed of your laser will decrease a lot if you are trying to cut on a thick surface. On thinner metals, the laser can perform better and cut with much more ease. A thick surface has a small processing parameter window. When you have a smaller window, it is harder to cut the surface, and it uses more energy. That makes it harder for your machine to cut and dial into the surface. If you do need to cut a thicker surface, consider using optical lenses.

The edges also become impacted when you have a thicker surface. The edge of the sheet that you have your sheet metal laser cutting service work on should be smooth and flat. With a thicker sheet, the edge will not follow the same shape, and it can stay rougher. If the sheet is hot, the issue does not happen as much, even if you have a thicker sheet. It is important to optimize the machine’s performance and get smooth metal for cutting.

The Power of the Laser

The way that your machine will react to your piece’s surface also factors into the metal laser cutting in NYC. The laser power is vital to think about with heavier sheets. If the machine has lower power, it is harder to cut the sheets. On the other hand, a higher-powered beam can easily cut the thick layers of metal. That will also ensure that your edges are flat.

Technology

With CO2 lasers, you can get cleaner corners and smoother edges. However, the thickness of the metal can cause the quality of the edges to decrease. Your sheet metal laser cutting service provider can help you choose the right laser for your material.

Choose the Best Metal Laser Cutting in NYC

When it comes to sheet metal laser cutting services, you need to consider the right factors. There are other factors that also play a role in the metal cutting process. If you have questions about the laser cutting process, feel free to contact Weldflow Metal Products today.